Delivering world-class manufacturing & supply chain services

We Provide Cost-Effective Solutions For Castings, Machinings, Forgings, Extrusions, Stampings & Bendings

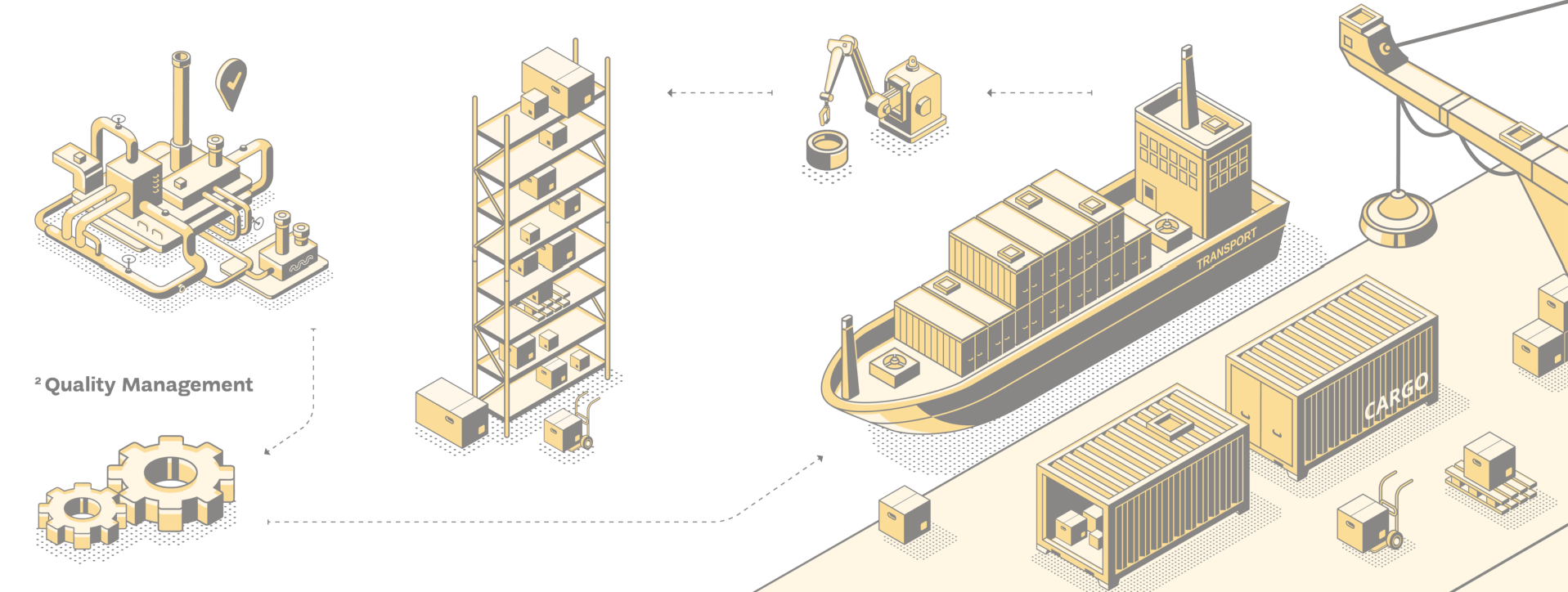

We help our customers find the right manufacturing sources, working with highly qualified, ISO-certified suppliers. Then we guide the manufactured parts to their final destination, managing each step in the supply chain process.

Competitive Manufacturing & Supply Chain Solutions

- Quick production lead times

- Just in time deliveries

- Engineering support

- World–Class supply chain services

- Short tooling lead times

- Faster time to market

— Partnership

Not Just Your Manufacturing Partner!

Our Services Include

- Manufacturing

- Purchasing

- Supply Chain & Warehousing

- Quality Management

- Engineering Support

- Software Solutions

- Forecasting

- Inventory Management Planning

Our Clients

Each of our clients are unique as their product